Perfect Info About How To Check Valve Timing

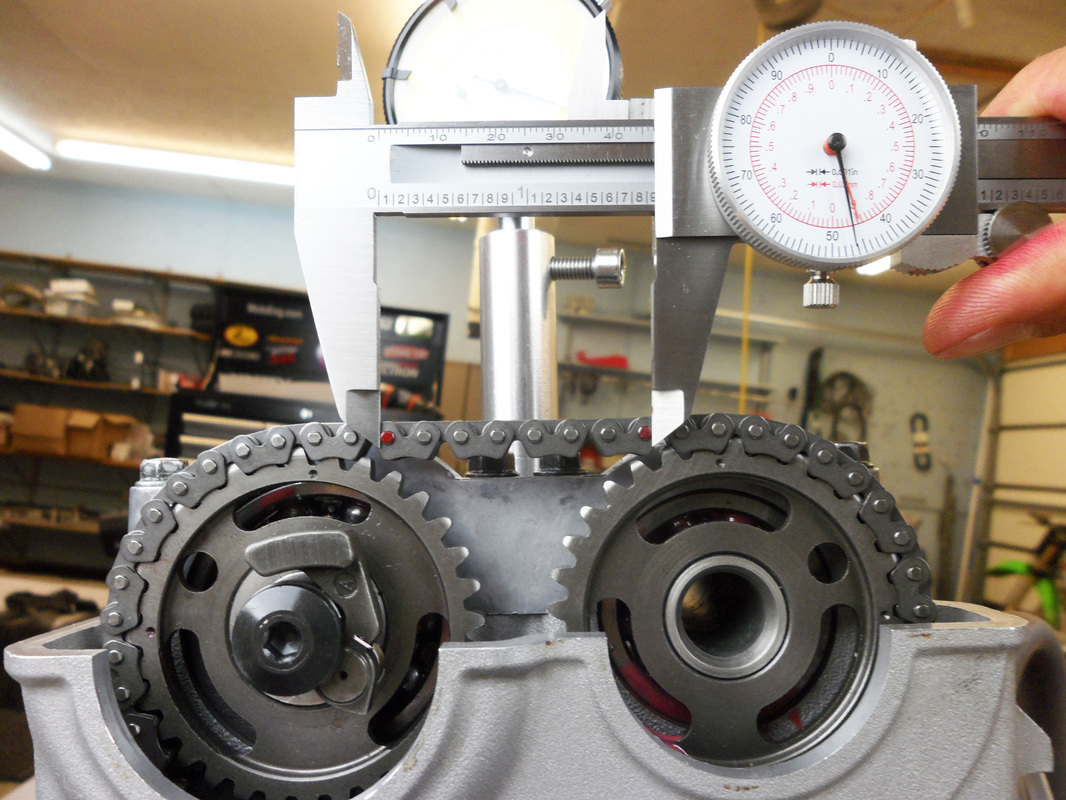

It is quite easy to determine tdc (in an engine with the head removed) with a dial gauge set on top of one of the pistons.

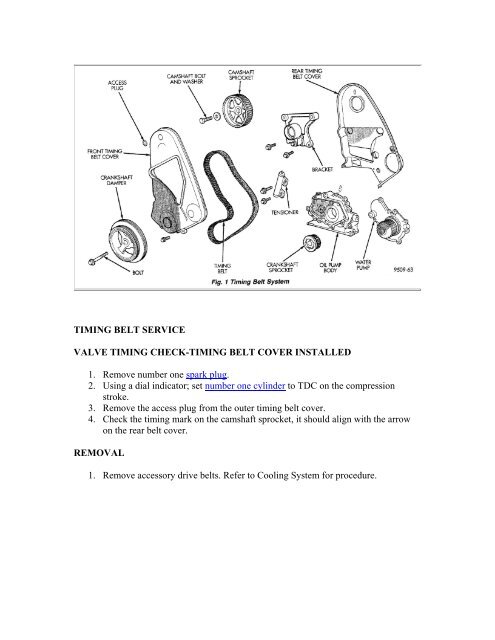

How to check valve timing. Rotate crank until the rockers on cylinder one are holding both valves open a little. P0010 p0011 p0012 p0013 p0014 p0015 p0020 p0021 p0022 p0023 p0024 p0025 p0028 p1349disclaimer: In the event that you didn’t find.

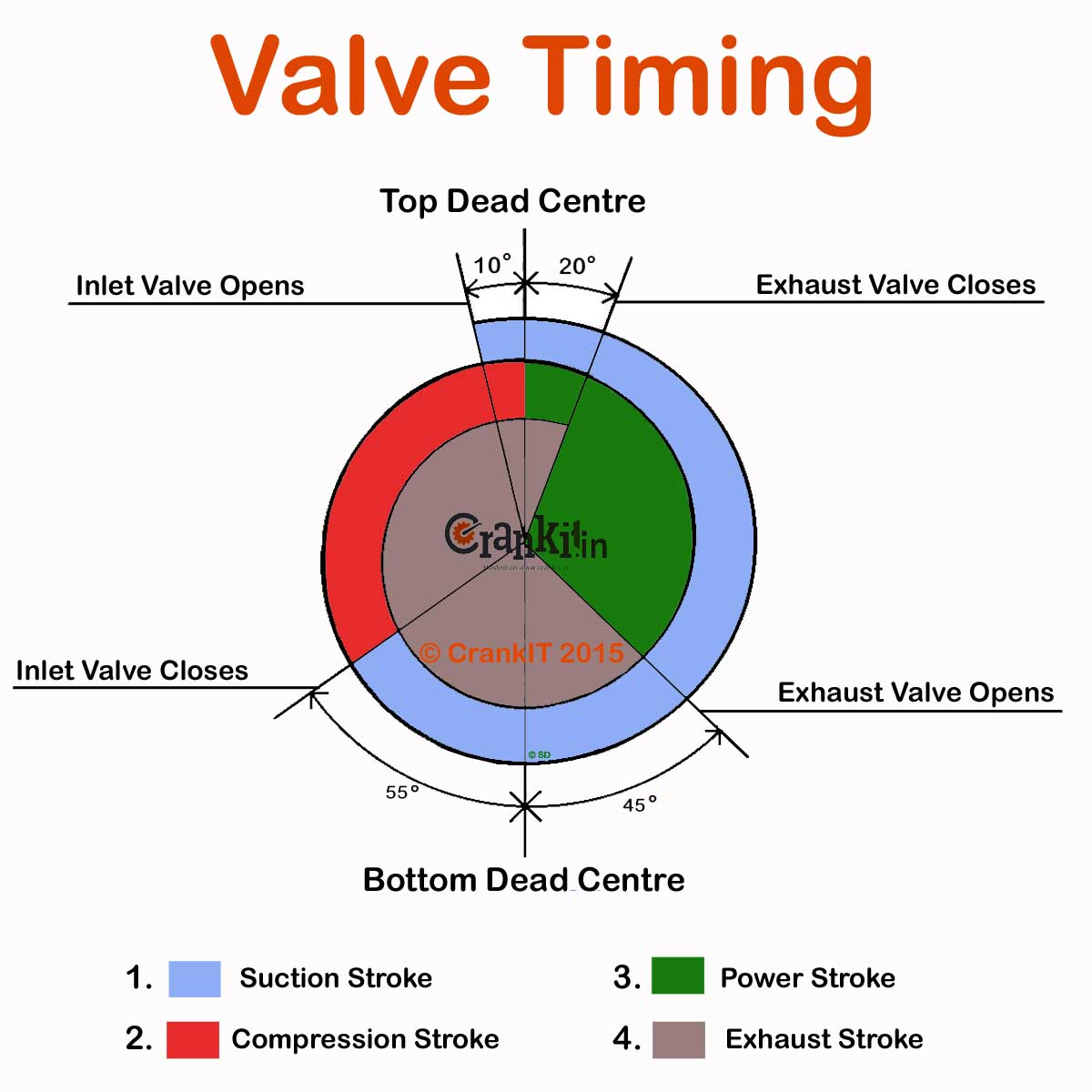

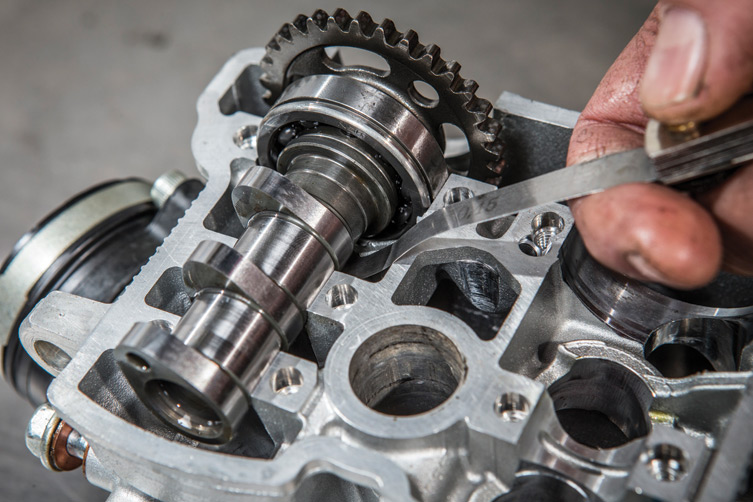

We consider that for the valve timing diagram, the valves open and close at the dead center positions of the piston. Remember to factor in the compressed thickness of your head gasket. Engine codes can vary from year/make/model and can include the following:

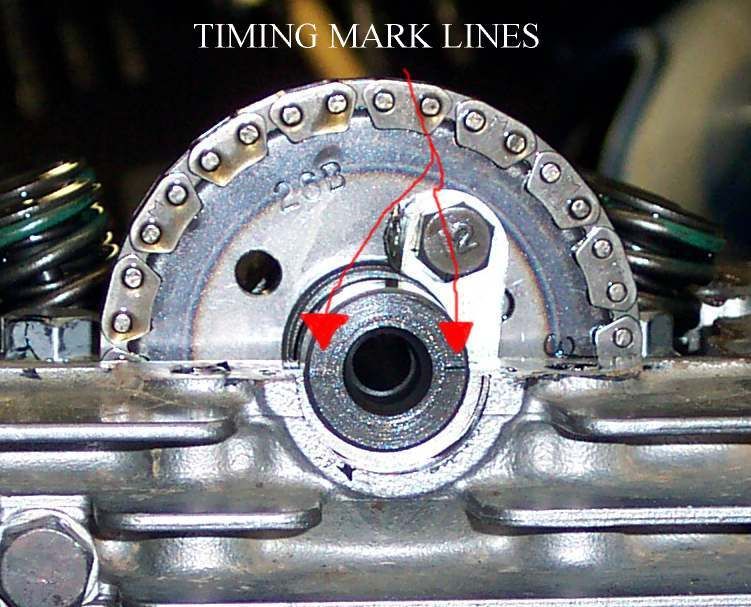

Slowly turn the crank clockwise until the lifter rises 0.050 inch. It is a universally accepted standard for checking cam timing. The timing for the cam now standardised.

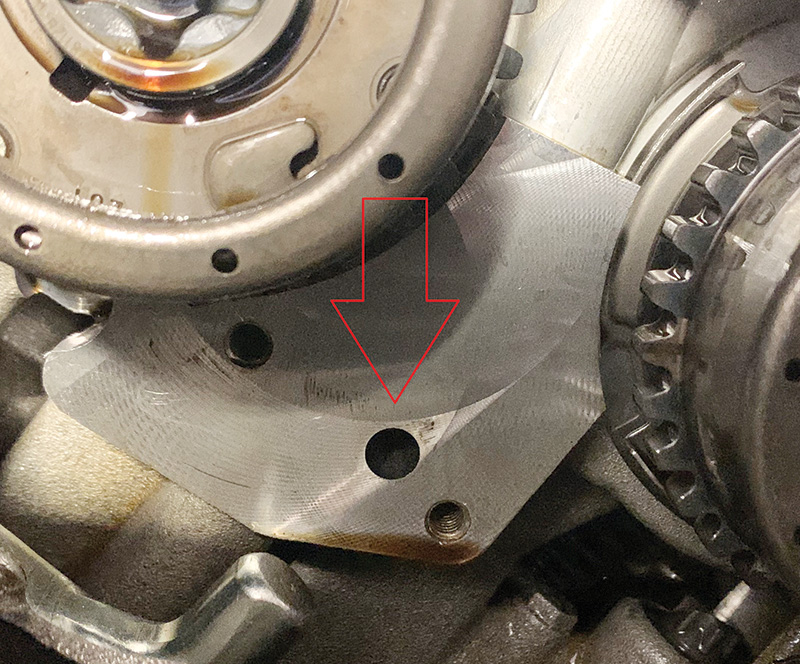

Measure the thickness of the clay under the valve impression to get the piston to valve clearance reading. Most existing systems manipulate the valve timing using a. An alternate method is to look at the timing marks on the flywheel.

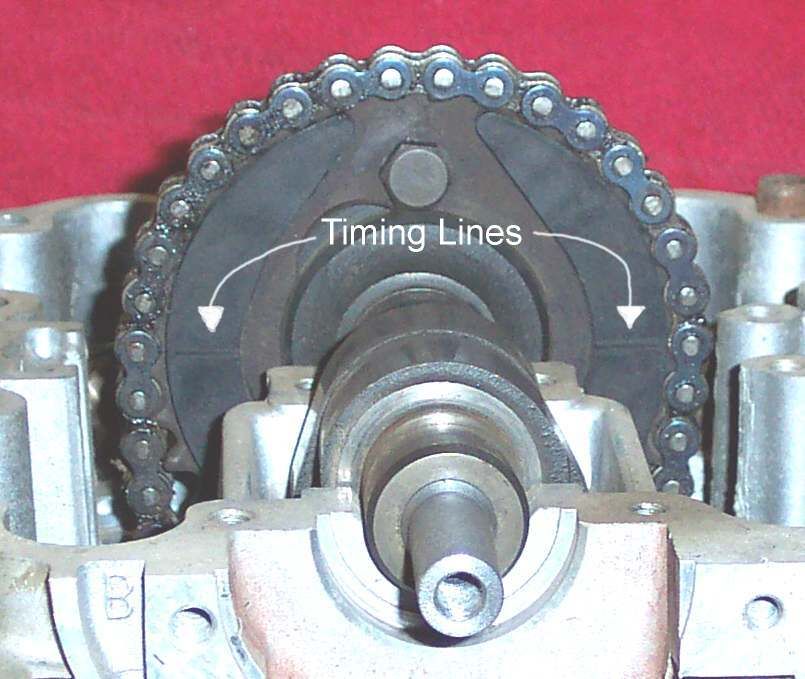

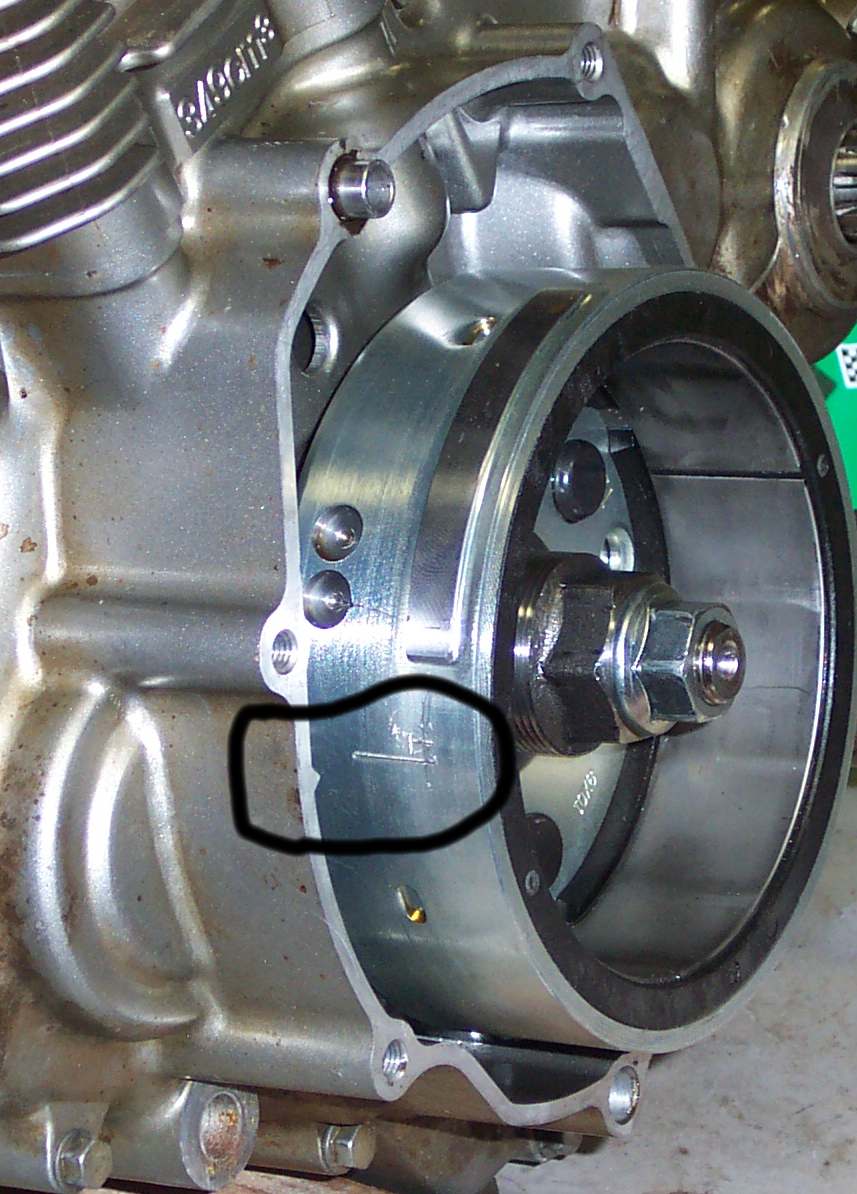

A method to check timing without removing timing covers, valve covers, or intake manifolds.for more training videos like this, visit schrodingers box quantum. Camshaft position actuator circuit bank 1. It is necessary in order to check the timing accurately for the exhaust rocker to be removed when checking the inlet valve timing and vice versa.

Look at the pointer and pulley. To see if your valves are bent, you must remove the timing belt and check each piston individually when the camshaft is in the tdc position. Electronic valve control (evc) systems attempt to optimize the valve timing over the entire range of possible engine speeds.